Giles Edwards: Difference between revisions

(1st pass) |

No edit summary |

||

| Line 1: | Line 1: | ||

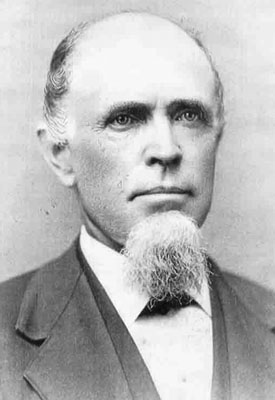

[[File:Giles Edwards.jpg|right|thumb|Giles Edwards]] | |||

'''Giles Edwards''' (born [[September 26]], [[1824]] in Merthyr Tydfil, South Wales; died [[April 26]], [[1892]] in [[Woodstock]]) was the furnace master for the [[Shelby Iron Works]] and the pioneer of coke-fueled blast furnaces in the [[Birmingham District]]. | '''Giles Edwards''' (born [[September 26]], [[1824]] in Merthyr Tydfil, South Wales; died [[April 26]], [[1892]] in [[Woodstock]]) was the furnace master for the [[Shelby Iron Works]] and the pioneer of coke-fueled blast furnaces in the [[Birmingham District]]. | ||

| Line 5: | Line 6: | ||

Edwards worked with James Henderson to convert the East Tennessee Iron Manufacturing Company's Bluff Furnace in downtown Chattanooga from charcoal to coked mineral coal in [[1860]]. | Edwards worked with James Henderson to convert the East Tennessee Iron Manufacturing Company's Bluff Furnace in downtown Chattanooga from charcoal to coked mineral coal in [[1860]]. | ||

In [[1862]] Edwards was hired by Selma investor John Lapsley to serve as assistant superintendent for the [[Shelby Furnace]], which was to be modernized. In [[1863]], with federal troops nearing Chattanooga, the Bluff Furnace was dismantled and its machinery hauled to the vicinity of [[Anniston]]. Edwards helped to build the new [[Oxford Iron Furnace]] with that equipment. He brought some of the un-needed parts back with him to Shelby Furnace. He supervised the production of iron rolled at the [[Shelby Rolling Mill]] which was used to clad the ''C.S.S. Tennessee''. | |||

In the years following the [[Civil War]], Edwards was employed by [[Josiah Gorgas]] to help rebuild the [[Brierfield Rolling Mill]] and the [[Bibb Furnace]]. He then served as land agent for the Thomas family's [[Pioneer Mining & Manufacturing Co.]] which, with his guidance, acquired more than 2,600 acres of ore mining land in [[1868]]. He resided in the former furnace master's house at [[Tannehill Ironworks]]. | |||

At the same time, Edwards acquired some property of his own in the vicity of [[Woodstock]] and began building the [[Edwards Furnace]] in [[1873]], using parts salvaged from [[Irondale Furnace|Irondale]] and Tannehill. It became the first in the state to be blown in with coke, just before the [[Alice Furnace]] was fired in [[Birmingham]]. He mined brown [[iron ore]] for use in his furnace, and also for sale to Oxmoor and other producers, who mixed it with the red ore from [[Red Mountain]]. | |||

The Edwards Furnace, in which [[Henry DeBardeleben]] was an investor, struggled to prosper in its fast-changing economic climate and was shut down several times for upgrades. It was able to produce as much as 30,000 tons of pig iron per day before it closed in [[1890]]. During one of the furnace's idle periods in [[1883]], Edwards accepted a job from the [[Eureka Company]] to rebuild the Oxmoor Furnace. | |||

Edwards was married to the former Salinah Evans. Their two daughters, [[Lydia McQueen|Lydia]] and [[Gertrude Pickens|Gertrude]], were married to [[James McQueen]] and [[D. W. Pickens]] in a double ceremony at their home in Woodstock in [[1899]]. Their oldest son, [[Thomas Edwards|Thomas]], became general manager of the [[Williamson Iron Co.]] and was burned to death when that furnace blew out on [[November 26]], [[1902]]. They also had two more sons, Joseph and Reuben. | |||

Giles Edwards died at home in [[1892]]. He and his wife are buried together in the McQueen plot at [[Oak Hill Cemetery]]. | |||

DeBardeleben eulogized him, saying: “Giles Edwards was a conceiver of big projects. He was one of the first men in the state to see the big possibilities ahead and to cast his lines and work accordingly. He was well informed on coke, coal and iron. He was a practical geologist and a scholar, had one of the best libraries in the state. He was a good draftsman besides, a first rate one and an excellent citizen, none better.” | |||

==External links== | |||

* [https://www.findagrave.com/memorial/96956933/giles-edwards Giles Edwards] at Findagrave.com | |||

{{DEFAULTSORT:Edwards, Giles}} | {{DEFAULTSORT:Edwards, Giles}} | ||

[[Category:1824 births]] | [[Category:1824 births]] | ||

[[Category:1892 deaths]] | [[Category:1892 deaths]] | ||

[[Category:Engineers]] | |||

[[Category:Furnace masters]] | [[Category:Furnace masters]] | ||

[[Category:Oak Hill burials]] | [[Category:Oak Hill burials]] | ||

Revision as of 10:34, 27 August 2023

Giles Edwards (born September 26, 1824 in Merthyr Tydfil, South Wales; died April 26, 1892 in Woodstock) was the furnace master for the Shelby Iron Works and the pioneer of coke-fueled blast furnaces in the Birmingham District.

Edwards immigrated to the United States in 1842 and worked as a draftsman for iron manufactories at Carobondale and Scranton, Pennsylvania. He rose to the position of superintendent at the furnaces in Tamaqua and Catasauqua, where he gained the notice of its designer, fellow Welshman David Thomas. After a brief posting at the Novelty Ironworks in New York, Thomas sent him to Chattanooga, Tennessee, partly in hopes that the change of climate might benefit his failing health.

Edwards worked with James Henderson to convert the East Tennessee Iron Manufacturing Company's Bluff Furnace in downtown Chattanooga from charcoal to coked mineral coal in 1860.

In 1862 Edwards was hired by Selma investor John Lapsley to serve as assistant superintendent for the Shelby Furnace, which was to be modernized. In 1863, with federal troops nearing Chattanooga, the Bluff Furnace was dismantled and its machinery hauled to the vicinity of Anniston. Edwards helped to build the new Oxford Iron Furnace with that equipment. He brought some of the un-needed parts back with him to Shelby Furnace. He supervised the production of iron rolled at the Shelby Rolling Mill which was used to clad the C.S.S. Tennessee.

In the years following the Civil War, Edwards was employed by Josiah Gorgas to help rebuild the Brierfield Rolling Mill and the Bibb Furnace. He then served as land agent for the Thomas family's Pioneer Mining & Manufacturing Co. which, with his guidance, acquired more than 2,600 acres of ore mining land in 1868. He resided in the former furnace master's house at Tannehill Ironworks.

At the same time, Edwards acquired some property of his own in the vicity of Woodstock and began building the Edwards Furnace in 1873, using parts salvaged from Irondale and Tannehill. It became the first in the state to be blown in with coke, just before the Alice Furnace was fired in Birmingham. He mined brown iron ore for use in his furnace, and also for sale to Oxmoor and other producers, who mixed it with the red ore from Red Mountain.

The Edwards Furnace, in which Henry DeBardeleben was an investor, struggled to prosper in its fast-changing economic climate and was shut down several times for upgrades. It was able to produce as much as 30,000 tons of pig iron per day before it closed in 1890. During one of the furnace's idle periods in 1883, Edwards accepted a job from the Eureka Company to rebuild the Oxmoor Furnace.

Edwards was married to the former Salinah Evans. Their two daughters, Lydia and Gertrude, were married to James McQueen and D. W. Pickens in a double ceremony at their home in Woodstock in 1899. Their oldest son, Thomas, became general manager of the Williamson Iron Co. and was burned to death when that furnace blew out on November 26, 1902. They also had two more sons, Joseph and Reuben.

Giles Edwards died at home in 1892. He and his wife are buried together in the McQueen plot at Oak Hill Cemetery.

DeBardeleben eulogized him, saying: “Giles Edwards was a conceiver of big projects. He was one of the first men in the state to see the big possibilities ahead and to cast his lines and work accordingly. He was well informed on coke, coal and iron. He was a practical geologist and a scholar, had one of the best libraries in the state. He was a good draftsman besides, a first rate one and an excellent citizen, none better.”

External links

- Giles Edwards at Findagrave.com